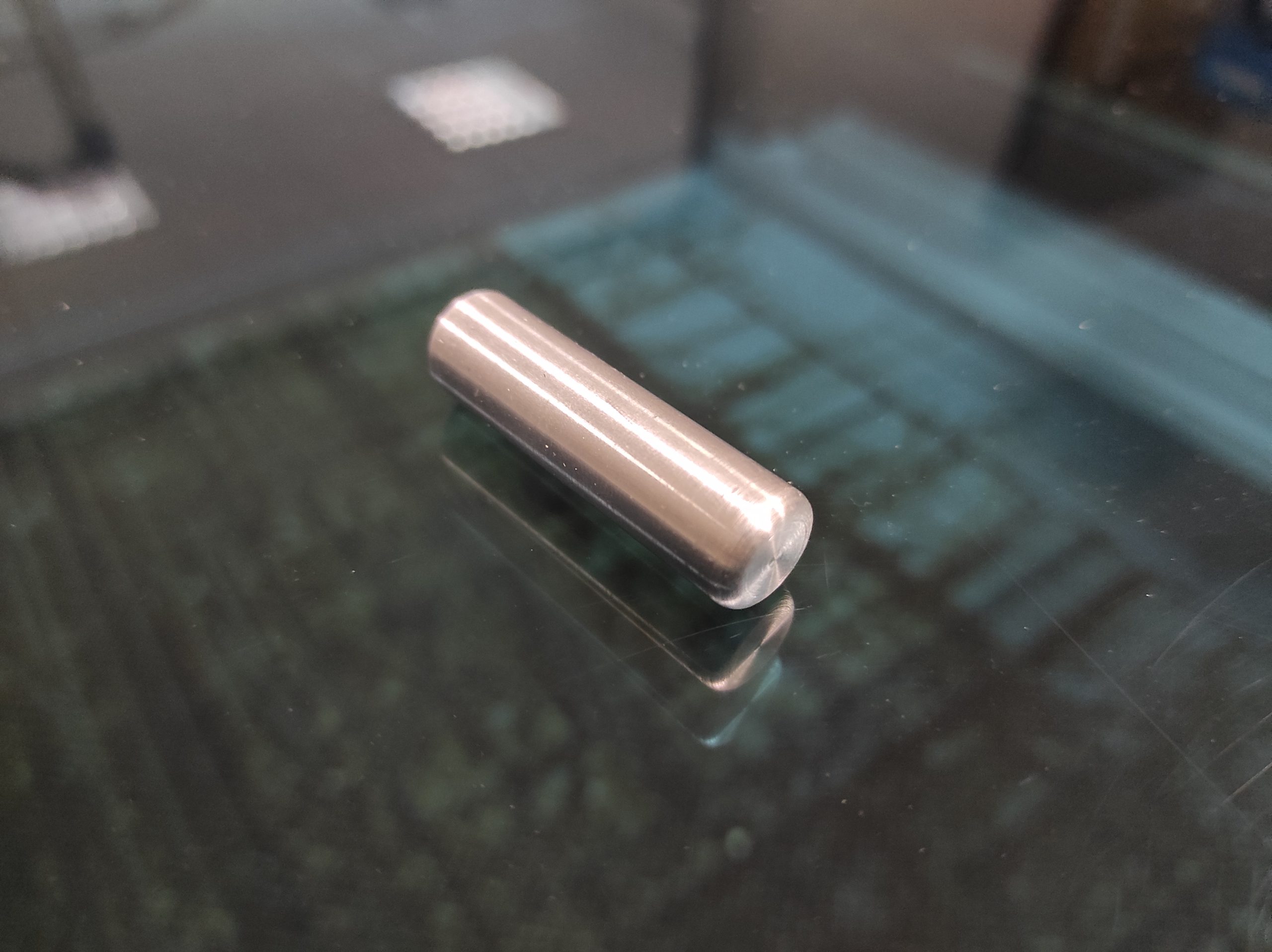

This is possibly the simplest lathe project possible – a simple straight pin (although we rounded over the edges to make it a bit easier to slide something on).

Since this is such a simple project, there’s no need to create a CNC program, instead the cuts can be made directly using the manual keyboard controls on the lathe. The stock closest in size to the 12mm necessary was a 20mm round bar of aluminum, so it was necessary to remove quite a bit of material.

Since the bar is relatively long compared to its diameter, before turning a center is drilled in the back and the tailstock is used to suppor the piece during machining. Once the diameter is correct (verified using calipers throughout the project), the corners are rounded simply using a file (first a larger and then a smaller one).

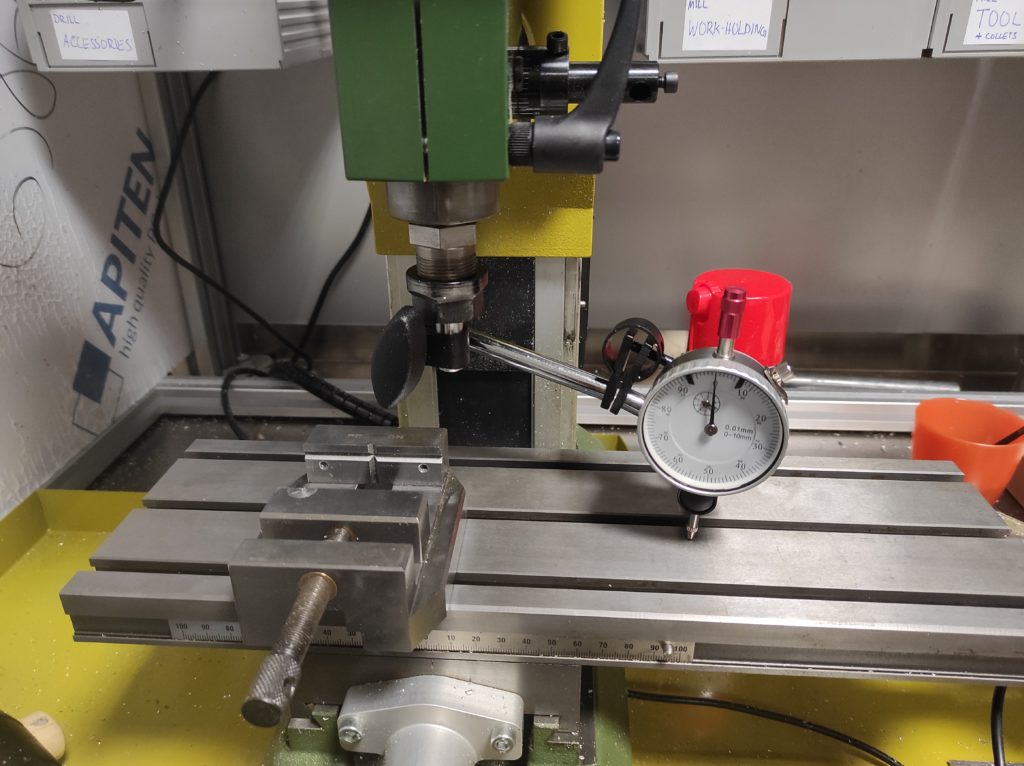

Since this pin is very round and has a precise 12mm diameter, we can hold it in the spindle of our milling machine using a collet. On the part that sticks out, an indicator arm can be attached so that the indicator can be swung around the spindle axis. This lets us measure whether or not the spindle is perpendicular to the table and to make precise adjustments to improve the surface finish when facing off parts.

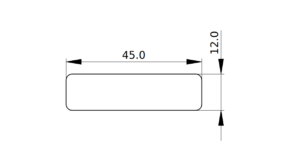

Since this is a manual project, there aren’t any files to download. A technical drawing also isn’t very useful, but here it is anyway: